Capacity Galaxy (AQX-CG)

What It Is

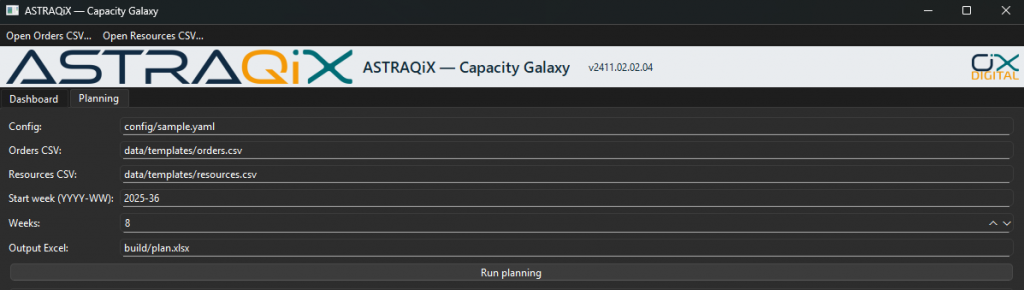

ASTRAQiX — Capacity Galaxy is the CiX platform for production and capacity planning. It brings machines, staff, and orders into one structured universe so that loads, schedules, and bottlenecks become transparent and manageable.

Core Capabilities

- Capacity & Scheduling: Allocation of jobs, shifts, and resources with clear load vs. capacity views.

- Order Management: Structured handling of jobs, BOMs, and priorities (incl. Excel/CSV import).

- Planning Engine: Bottleneck detection, drag-and-drop rescheduling, scenario options.

- Visualization: Gantt charts, heatmaps, weekly overviews, CI-compliant exports (Excel/PDF).

- Integration-Ready: SQL-based storage; scalable towards ERP, PLM/PDM, and other CiX platforms.

Outcome

From single jobs to the entire production cosmos: ASTRAQiX delivers clarity, predictable schedules, and confident decision-making across the shop floor.

Integration

- Desktop-App with SQL Server Express; ready to scale to full SQL Server.

- Future web front-end via shared REST/API core.

- Designed to connect with EQUinnoX (cost/ROI scenarios) and LYRAQiX (workflow/ticketing).

Industry Modules

Food & Beverage (AQX-CG / Food)

What it solves

Planning for lines with cleaning/changeovers, shelf life, and allergen/organic requirements — with full batch transparency.

Functions

- Cleaning (CIP/SIP): Line/shift cleaning plans, allergen change matrix, digital logs (HACCP/IFS/BRC ready).

- Product Changeovers: Sequence optimisation incl. rinse/setup times; Organic ↔ Conventional with hard separation rules.

- Packaging Change: Label/GTIN switch, material/format parts, seasonal layouts; print straight from planning.

- Automatic Lot-Size Optimisation: Minimises changeovers while honouring MHD/shelf life, FEFO, and stock targets.

- Raw Materials & Recipes: Planned vs. actual consumption, yield tracking, approved alternates.

- In-Process Quality: Check plans, temperature/humidity logs, quarantine stock, recall scenarios.

- Traceability 1-up/1-down: End-to-end batch genealogy down to case/pallet.

- API Integration: Fully integrable with ERP / existing PPS, plus LIMS/label printing, scales/IoT.

Benefits

- Less downtime via optimised cleaning and changeover sequence.

- Safe allergen and organic segregation with audit-proof documentation.

- Higher yield, less rework and scrap.

- On-time delivery using FEFO- and shelf-life-driven planning.

- Full raw-to-customer visibility — recall readiness in minutes.

Manufacturing (Non-Food) (AQX-CG / MFG)

What it solves

Finite scheduling across machines, teams, and tools — from ETO/MTO to serial MTS/ATO.

Functions

- Setup & Sequence Optimisation (SMED): Setup families, rules, and automatic clustering.

- Finite-Capacity & Constraint Management: Drag-and-drop, scenarios, capable-to-promise simulations.

- BOM & Changes: ECN/ECR impact visible in the plan; PDM/PLM hooks across the CiX stack.

- Tools/Moulds & Maintenance: Lifecycles, counters, and planned service windows from within planning.

- Material Availability: Alternates, Kanban/min-max, purchase/EDI dates.

- Quality & Deviations: NC/CAPA workflows via LYRAQiX.

- OEE & Downtime Capture: Root-cause analytics and heatmaps.

Benefits

- Shorter lead times, lower WIP, reliable due dates.

- Fewer changeovers and better line utilisation.

- Change-resilient planning that “understands” BOM/ECN effects.

- Higher asset availability via coordinated maintenance windows.

Chemical / Oil & Gas (AQX-CG / COG)

What it solves

Campaign and batch planning across reactors/units, tanks, and utilities — with compliance and LIMS integration.

Functions

- Campaign Planning & Blending: Grades/recipes, flush logic (incl. rinse volumes), tank/silo level constraints.

- Unit Constraints: Reactors, columns, heat exchangers; parallel/secondary resources; utilities (steam/power) as hard limits.

- Quality & LIMS: Test points, release status, off-spec handling and re-blend options.

- Genealogy & Dangerous Goods: Batch trees, GHS/REACH/ADR master data, full audit trail.

- Turnaround/Shutdown: Integrated planning of outages and permit-to-work (via LYRAQiX).

- Interfaces: DCS/SCADA/historians (OPC/REST) plus ERP/PPS.

Benefits

- Higher yields and fewer off-specs through sequence- and utilities-aware planning.

- Compliant, audit-ready operations with complete genealogy.

- Better tank/terminal utilisation and reduced flush/changeover costs.

- Predictable turnarounds with minimised opportunity cost.